What we offer

Production Paint & Powder Coating Partner to many of the world’s most trusted brands

We provide liquid and powder coating services to some of the world’s most trusted brands and their supplier networks. We’re not a job shop. We build custom programs for our customers with value add services and bespoke logistics solutions. We have 8 production lines and produce hundreds of thousands parts per day. We have a fully staffed & trained QA department and dedicated customer experience specialists for each customer. Sound good? Let’s talk.

WHY ACME

We’re the last stop in more than 20 global supply chains. Coating is a small but critically important cost item for our customers. We get it. 10% of the cost. 100% of what the customer sees. Parts need to look good and need to be produced quickly. We’ve built our business to be the ideal production paint partner for global brands and their suppliers.

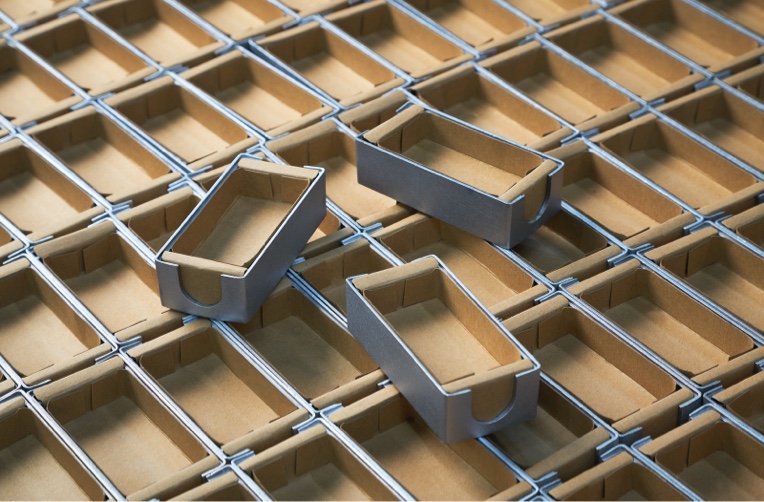

High Volume Capability

8 production areas. 3 powder lines. 3 liquid lines. Hundreds of thousands of parts per day. OEM overflow work.

Custom Production Partnerships

20+ global supply chains. Value added services. Dedicated customer experience professionals. Tailored logistics solutions. Easy on you.

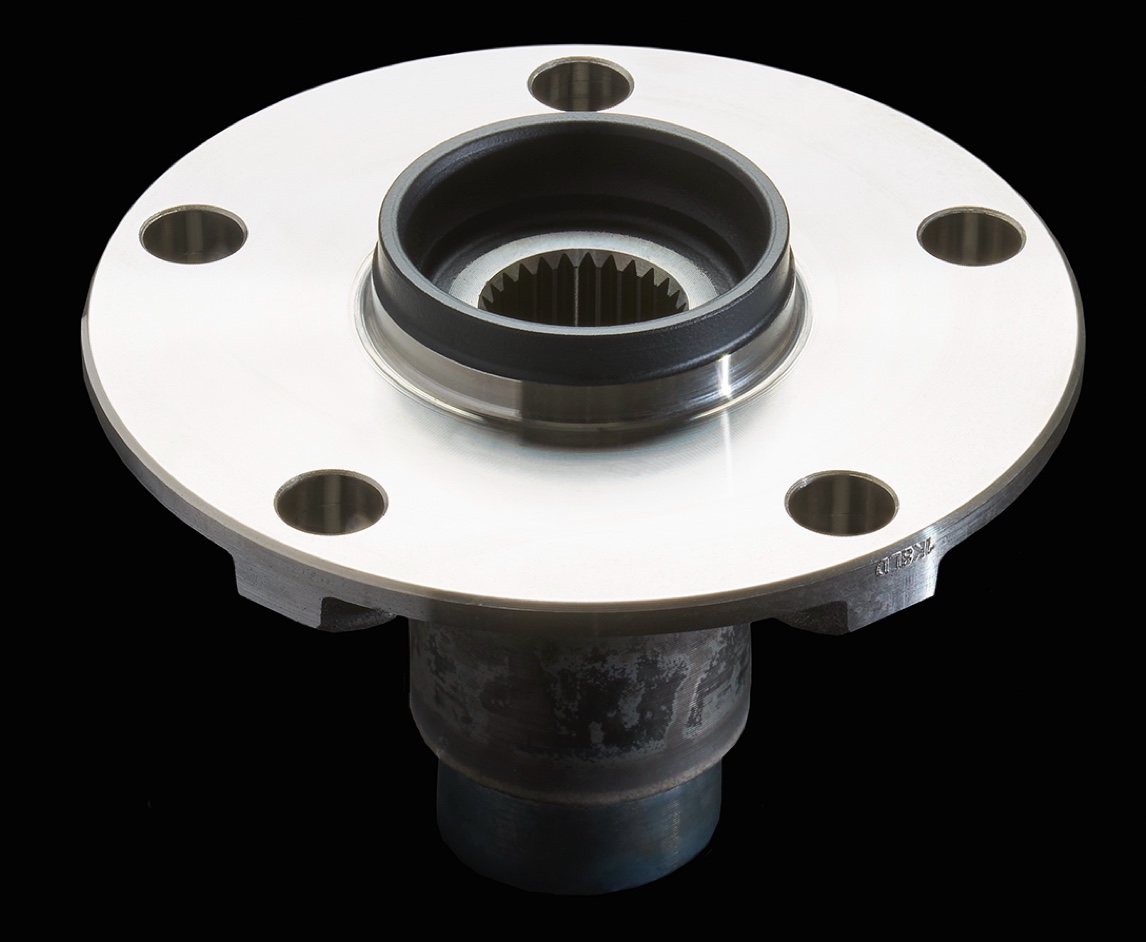

World Class Quality

ISO9001:2015 certified. CQI certified. AAMA certified Tier 2 to Ford, Lincoln, Nissan, Subaru, and Toyota. Fully trained QA department.

Large Part Capability

Window size of 26’ x 8’ x 4’. Parts weighing up to 1,000 lbs. Can handle parts up to 40 feet length in small volumes.

Our People

For us to win, our customers have to win. We get it. Despite our growth, we try to be easy to do business with.

Environmental Commitment

Environmental Commitment

Environmental Commitment

ISO 14001:2015 certified. Reclaim and reuse powder. Converting equipment to highest energy efficiency standards. Limit usage of high VOC liquid paints.

Capabilities & Results

The case studies below present a variety of examples of how our volume capabilities and willingness to build custom production programs have helped to create value for our customers and their customers.